Have you ever wondered how a tiny component can control massive machines or protect entire systems? That’s exactly what electrical relays do. They’re one of those behind-the-scenes heroes in both everyday electronics and large-scale industrial setups. In this blog, I’ll walk you through what relays really are, how they work, and where we see them in action—whether it’s in your home, your car, or the heart of a factory.

What is an Electrical Relay?

An electrical relay is an electrically operated switch that uses an electromagnet to control one or more sets of contacts. Relays allow a low-power signal to control a high-power circuit, providing isolation and control flexibility.

Components of Electrical Relay

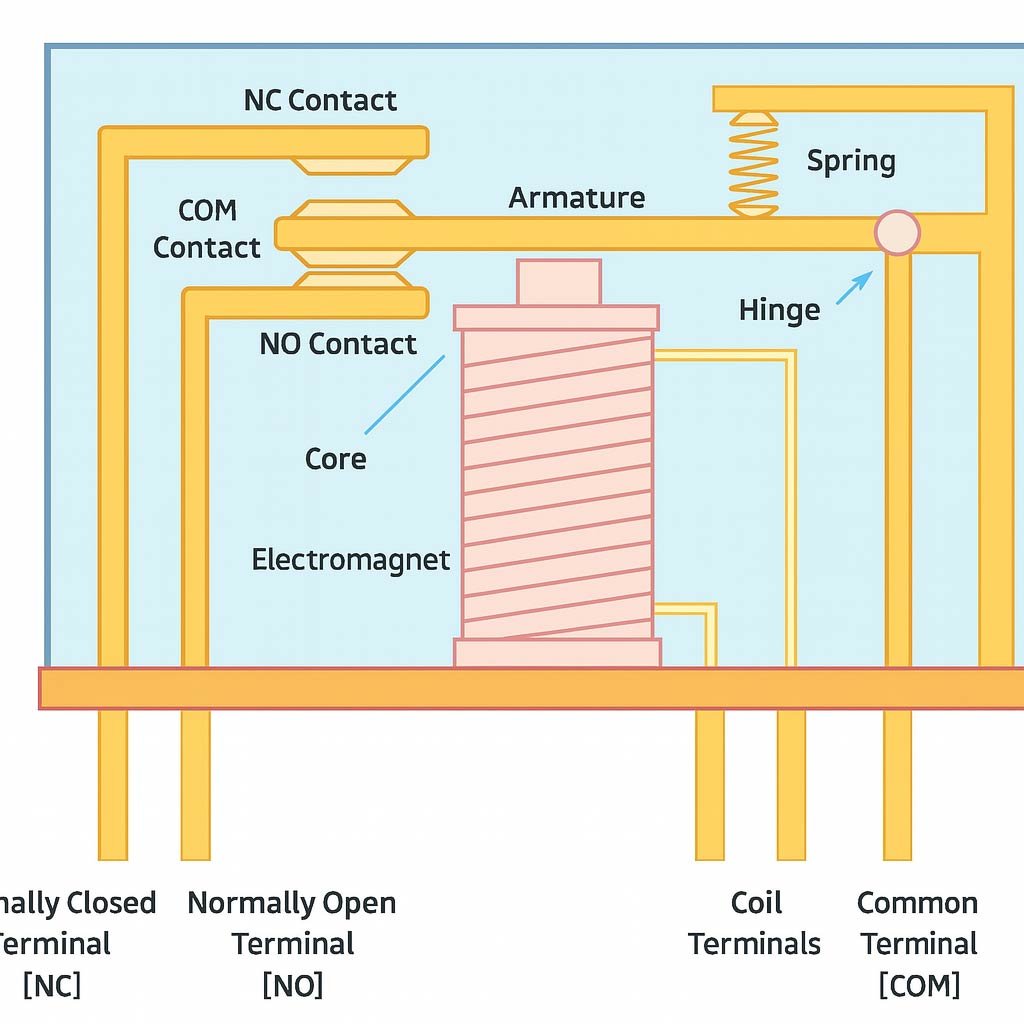

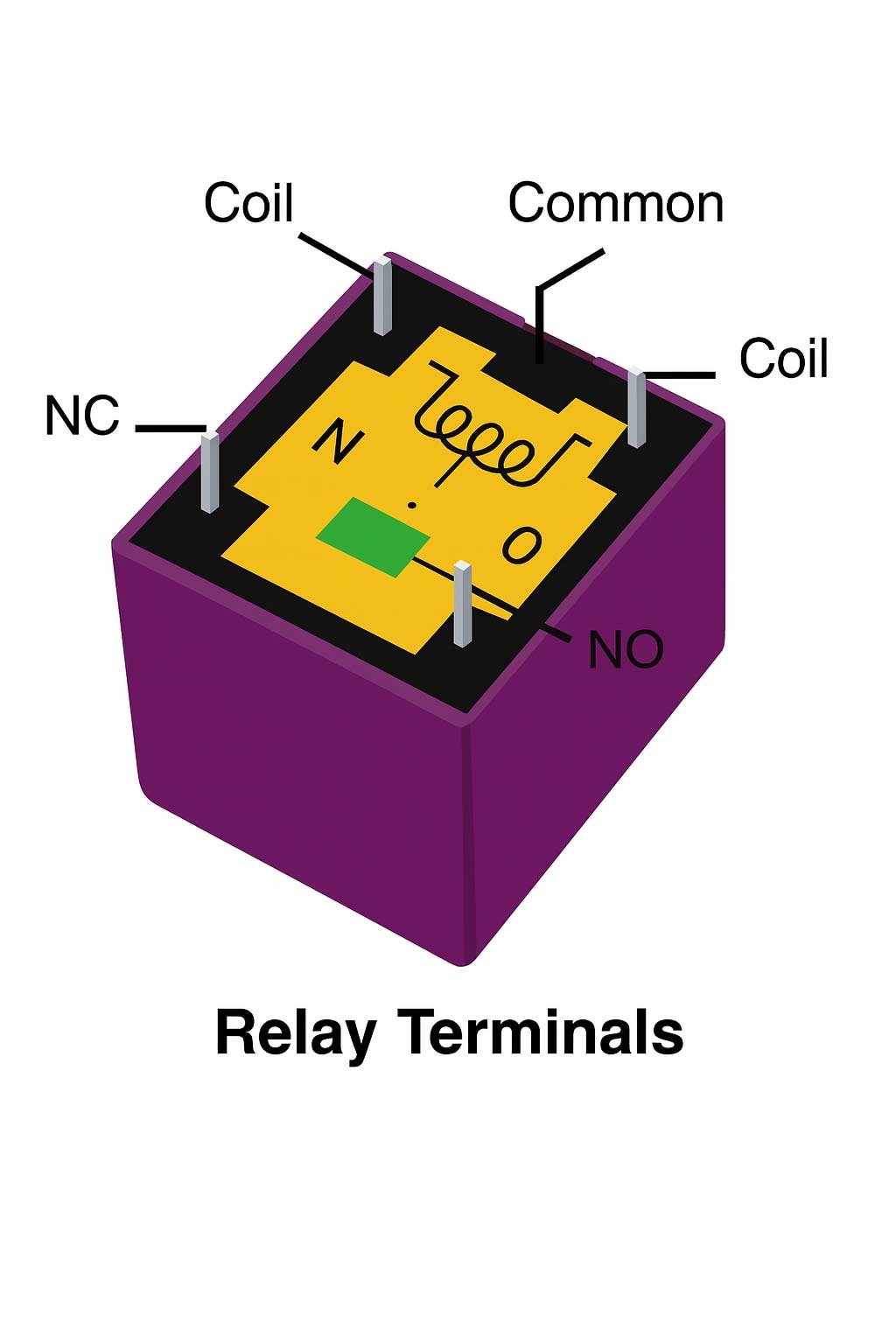

- Electromagnet (Coil): The core component of a relay is its electromagnet, which generates a magnetic field when an electric current passes through it.

- Armature: A movable iron lever or arm that is attracted to the electromagnet when it is energized.

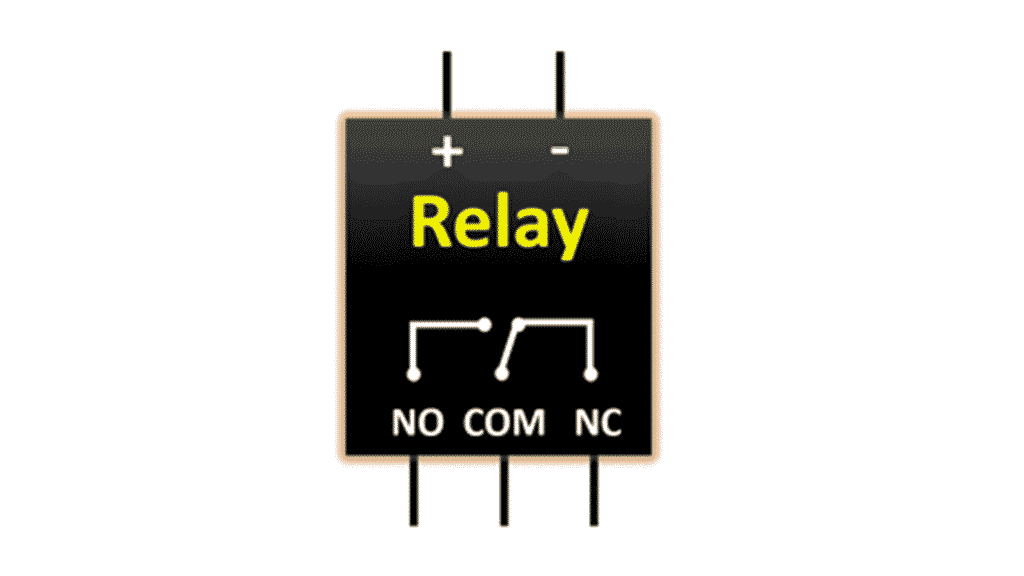

- Contacts: These are the conductive parts that open or close to control the circuit. There are typically three types of contacts:

- Normally Open (NO): These contacts are open (disconnected) when the relay is de-energized and close (connect) when the relay is energized.

- Normally Closed (NC): These contacts are closed (connected) when the relay is de-energized and open (disconnect) when the relay is energized.

- Common (COM): The terminal that connects to either the NO or NC contacts depending on the relay’s state.

How Does a Relay Work?

Here we will learn how the ordinary type of relay works

- Activation: When a small voltage is applied to the relay coil, it creates a magnetic field.

- Movement: The magnetic field attracts the armature, causing it to move.

- Switching: The movement of the armature opens or closes the relay contacts. This action either completes or interrupts the circuit connected to the relay.

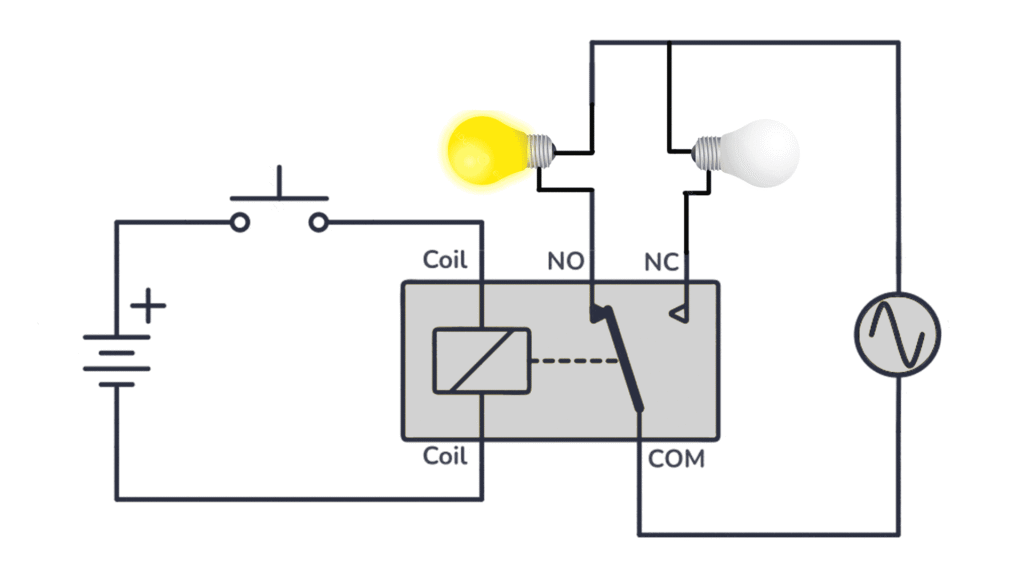

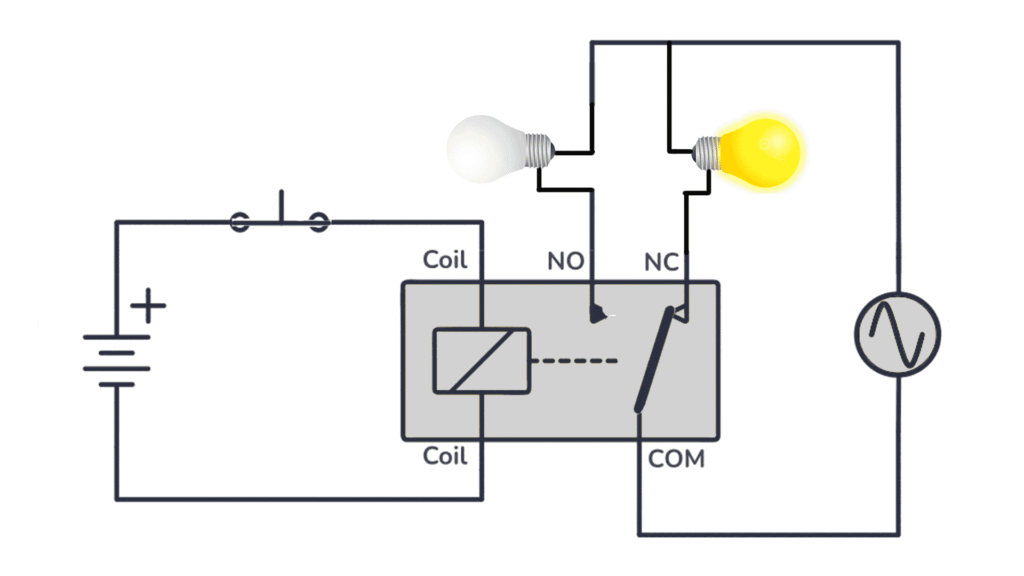

Relay Operation Example

Imagine a simple scenario where you want to control a high-voltage two lamps using a low-voltage switch. Without a relay, you would need a switch that can handle the high voltage, which can be bulky and expensive.

Also we need to control one of the two lamps only work at a time, so we will connect one lamp on the normally closed contact, and the other one on the normally open contact

With our relay:

- Low-Voltage Control Circuit: The low-voltage switch is used to energize the relay coil.

- High-Voltage Circuit: The relay contacts control the high-voltage two lamps.

Before flipping the low-voltage switch, the first lamp is on and the second lamp is off.

When you flip the low-voltage switch, it energizes the relay coil, causing the relay contacts to close and complete the high-voltage circuit, turning on the second lamp and turning off the first one.

Types of Relays

These relays are classified based on their different operation principles

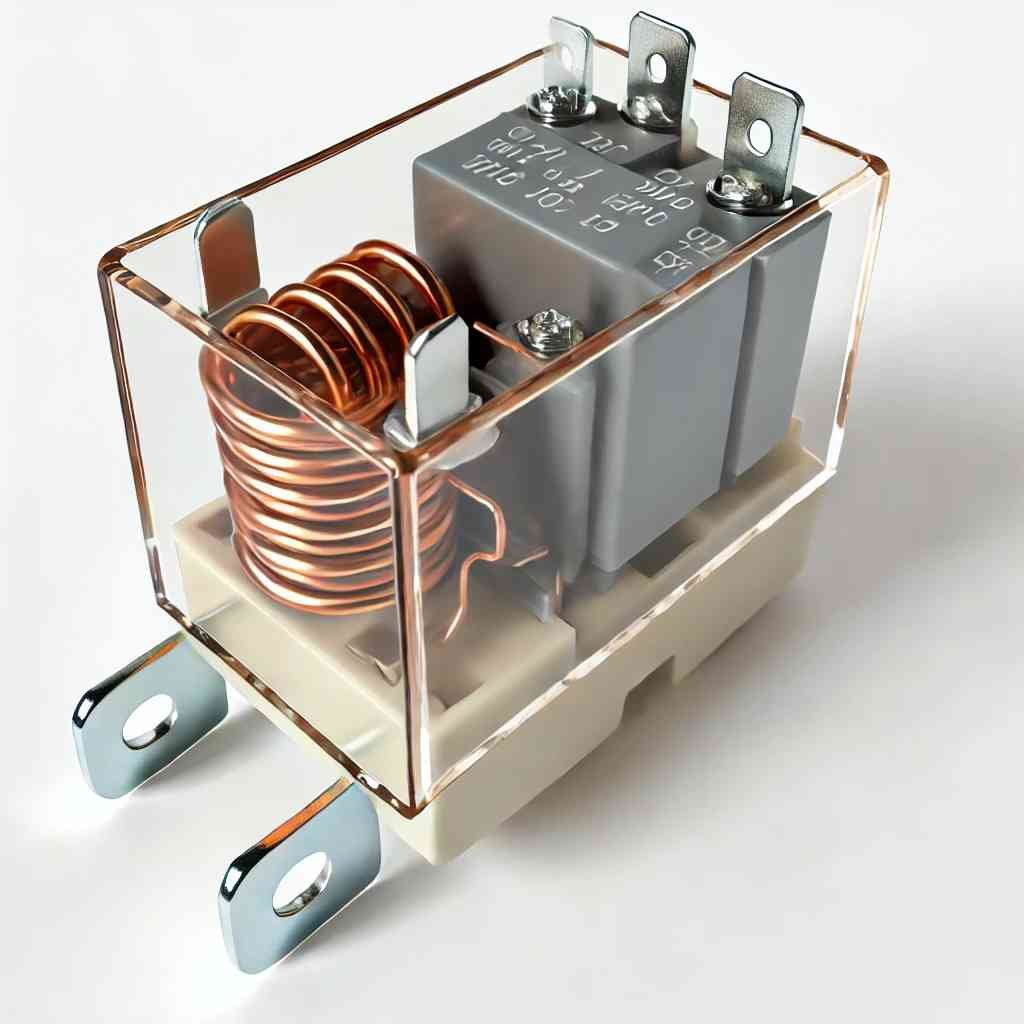

1-Electromechanical Relays (EMR)

They are the most common type and are suitable for a wide range of applications.

These use an electromagnet to operate the switching mechanism.

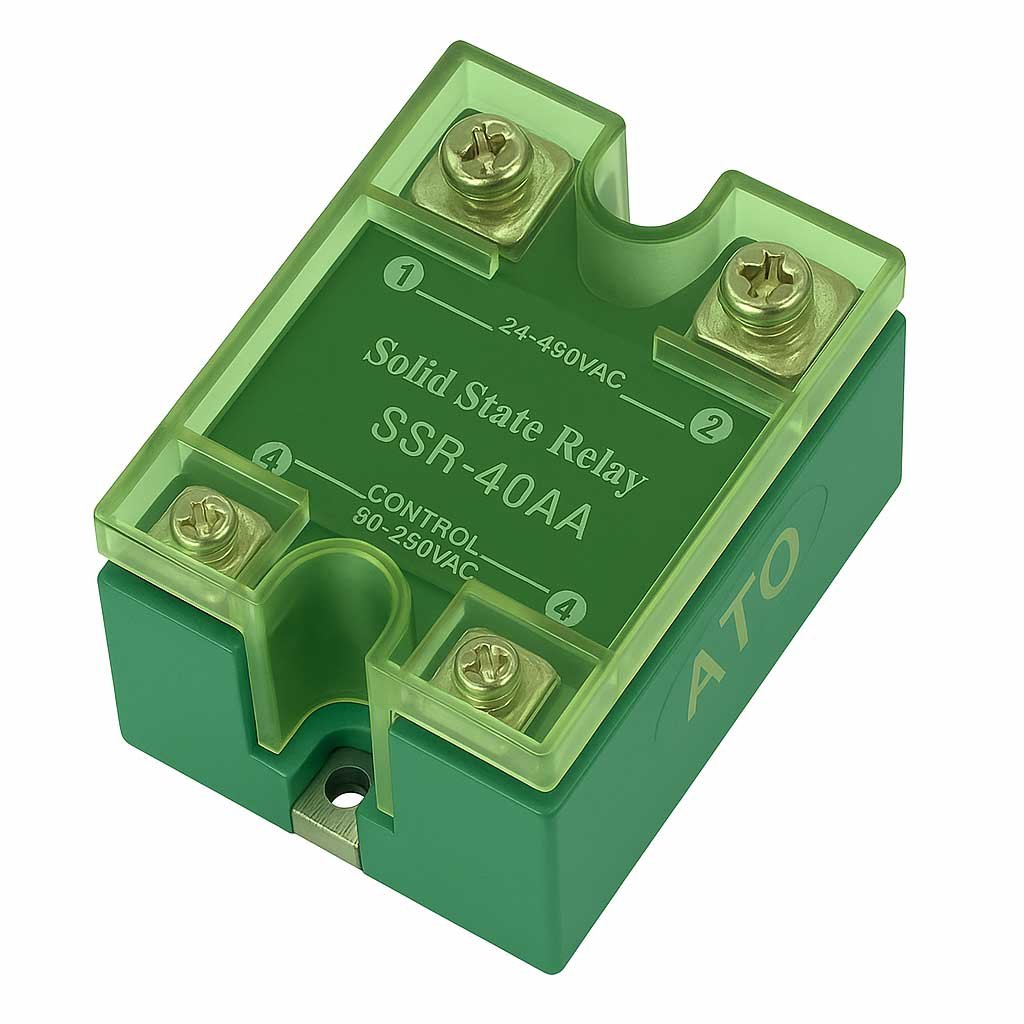

2-Solid-State Relays (SSR)

Semiconductor components are used here to perform the switching function without moving parts. They offer faster switching speeds and greater reliability but can be more expensive.

3-Hybrid Relays

Imagine a tiny switch that combines the best of both worlds—the speed and silence of electronics with the strength and durability of mechanical relays. That’s what a hybrid electric relay does.

Think of it like this: the electronic part handles the quick, clean switching without sparks, while the mechanical part takes over for the heavy lifting—carrying the full current load when needed. It’s smart, efficient, and perfect for situations where reliability really matters, like in industrial machines or energy systems.

4-Reed Relays

Picture two tiny metal reeds sealed inside a small glass tube, just waiting for a magnetic field to bring them together. That’s the heart of a reed relay.

When a coil nearby is energized, it creates a magnetic field that pulls the metal reeds together—click!—and the circuit closes. No moving parts outside, no noise, and super fast response. Because it’s sealed, it’s also protected from dust and moisture, making it perfect for delicate electronics, medical devices, or even test equipment where precision is everything.

5-Time Delay Relays (Timers)

Unlike regular relays that switch instantly, time delay relays wait before turning on or off. You can set them to delay for a few milliseconds or several minutes—depending on your needs. They’re super useful in situations like giving a motor time to cool down, letting lights stay on briefly after a machine shuts off, or making sure systems start in the right order.

Applications of Relays

- Automotive: Relays are used to control high-current devices like headlights and horns from low-current switches on the dashboard.

- Home Appliances: In appliances like washing machines and ovens, relays control high-power elements such as heating elements and motors.

- Industrial Automation: Relays are used to control machinery, alarms, and signaling systems, providing isolation between control and power circuits.

- Telecommunications: In telephone exchanges and networking equipment, relays are used to route signals and ensure reliable operation.

Advantages of Relays

- Isolation: Relays provide electrical isolation between control and power circuits, enhancing safety.

- Flexibility: They allow control of high-power devices with low-power signals, enabling the use of simple control systems.

- Multiple Outputs: A single relay can control multiple circuits through its different sets of contacts.

Disadvantages of Relays

- Mechanical Wear: Electromechanical relays have moving parts that can wear out over time, reducing their reliability.

- Price: Solid-State relays are pretty good relays but more expensive than electromechanical relays.

- Speed: Relays generally have slower switching times compared to solid-state alternatives.

- Size: Traditional electromechanical relays can be bulkier compared to solid-state relays.

Conclusion

Electrical relays are versatile and essential components in modern electronics and electrical systems. They provide an efficient means to control high-power circuits with low-power signals and offer valuable isolation between different parts of a system. By understanding how relays work and their various applications, you can better appreciate their role in making electrical and electronic systems more reliable and flexible.

Whether you’re an engineer, technician, or simply a curious mind, exploring the functionality of relays reveals the intricate balance between simplicity and effectiveness in electrical design.