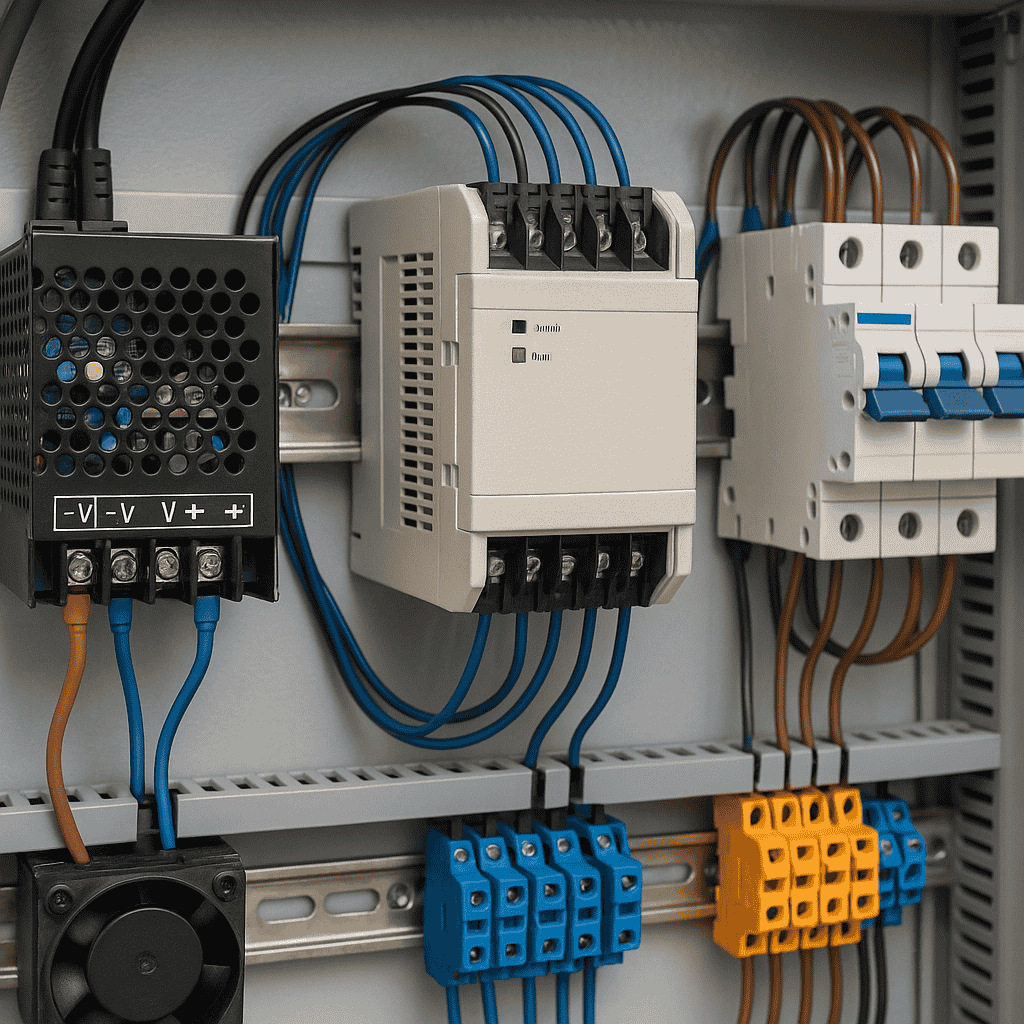

1. What Is a Control Circuit?

A control circuit is the part of an electrical system responsible for controlling devices like contactors, relays, timers, sensors, and indicators. It doesn’t directly power heavy loads like motors or heaters but instead manages the commands (start, stop, delay, reverse, etc.).

Example: When you press a Start button on a control panel, you’re interacting with the 24V control circuit—not the 220V power circuit.

2. Safety Comes First: Low Voltage = Low Risk

The most important reason for using 24V is safety.

- 24V is considered Extra-Low Voltage (ELV) by IEC and NEC standards.

- It is non-lethal under normal conditions and reduces the risk of electric shock.

- Safer to use in wet or humid environments or for systems operated by untrained personnel.

Even if someone accidentally touches a live 24V wire, the risk of severe injury or death is extremely low.

3. Compliance with Standards

Global electrical standards like:

- IEC 60204-1 (Safety of Machinery – Electrical Equipment)

- NFPA 79 (U.S. Electrical Standard for Industrial Machinery)

recommend or require that control circuits use ELV (typically 24V DC or AC) for operator interfaces, especially when exposed to human interaction.

This helps manufacturers ensure compliance and avoid legal or safety issues.

4. Protection of Components and Equipment

Control devices like sensors, PLCs, relays, and switches are sensitive to voltage surges.

- Using 24V (especially DC) minimizes arcing and extends component life.

- DC control systems provide stable operation with lower electromagnetic interference (EMI).

- Damage due to short circuits is much easier to manage in 24V systems.

5. Easy Integration with Modern Automation

Modern systems rely heavily on digital control, microcontrollers, and PLCs, which operate at low voltages.

- Most PLC input/output (I/O) modules are rated for 24V DC.

- Many industrial sensors (proximity, photoelectric, etc.) are designed to run on 24V DC.

- Easier to interface with microcontrollers like Arduino, Raspberry Pi, etc.

6. Energy Efficiency in the Control Section

Even though 24V might need a step-down transformer or power supply, the overall energy used by control circuits is minimal. The lower voltage allows the use of:

- Smaller wires

- Lower insulation requirements

- Compact and efficient components

This makes panels cleaner, cheaper, and easier to maintain.

7. Can 220V Be Used in Control Circuits?

Technically, yes. Some older systems still use 110V or 220V AC for control, especially for contactor coils or indicator lamps. However:

- It poses a greater safety risk.

- Makes panel maintenance more dangerous.

- Increases the chance of accidental contact injuries.

For these reasons, the industry has shifted towards 24V for nearly all control and interface functions.

Conclusion

Using 24V in control circuits isn’t just a preference—it’s a standardized safety practice that offers practical benefits in design, maintenance, and long-term operation. Whether you’re designing a control panel or working in industrial automation, understanding why 24V is used will help you build safer and more efficient systems.