In industries like oil and gas, chemical plants, and grain silos, safety is a top priority—especially where flammable gases or dust are present. That’s where ATEX-certified explosion-proof equipment becomes essential.

In this blog, we break down what ATEX is, how to read its markings, and the safety zones and protection types it defines.

What Is ATEX?

ATEX stands for “Atmosphères Explosibles”, meaning Explosive Atmospheres in French. It refers to two EU directives that regulate the use of equipment in hazardous environments:

- 2014/34/EU – For manufacturers of equipment

- 99/92/EC – For end users in workplaces

These directives ensure that electrical and mechanical equipment will not cause explosions in areas with flammable gases, vapors, or dust.

How to Read ATEX Markings

Example:

CE Ex II 2G Ex db IIC T6 Gb

Let’s decode it:

| Marking | Meaning |

|---|---|

| CE | Complies with European safety standards |

| Ex | Explosion-proof equipment |

| II | For surface industries (oil, gas, chemical) |

| 2G | Equipment category (high protection, gas environment) |

| Ex db | Type of protection (flameproof) |

| IIC | Gas group (hydrogen, acetylene – highly explosive) |

| T6 | Max surface temperature = 85°C |

| Gb | Equipment Protection Level for Zone 1 |

Equipment Groups

- Group I – Used in underground mining (methane or coal dust)

- Group II – Used in surface industries (factories, oil & gas)

Gas or Dust Environment?

- G – Gas, vapor, or mist

- D – Combustible dust

Equipment Categories and Safety Zones

| Category | Level | Zone | Risk |

|---|---|---|---|

| 1G / 1D | Very High | Zone 0 / 20 | Continuous presence of explosive atmospheres |

| 2G / 2D | High | Zone 1 / 21 | Explosive atmospheres likely to occur |

| 3G / 3D | Normal | Zone 2 / 22 | Rare or short explosive presence |

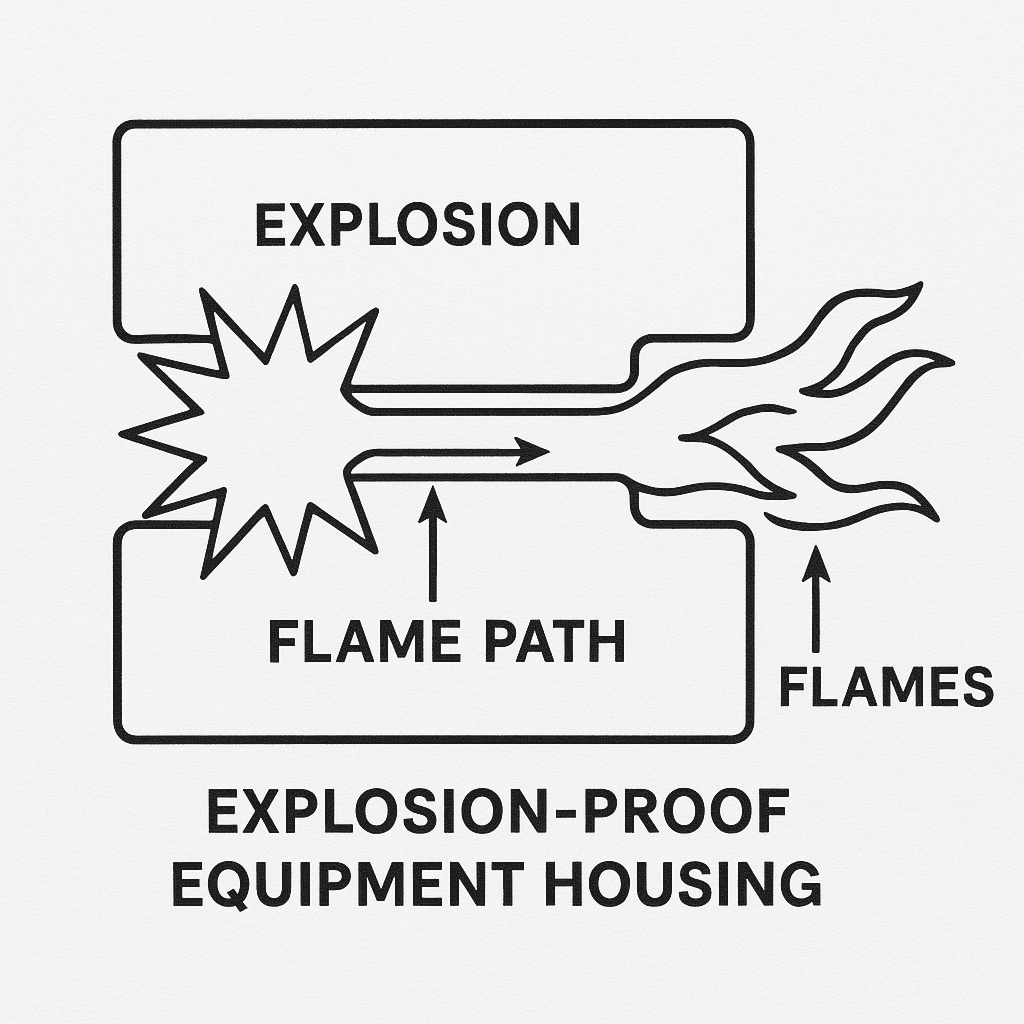

Types of Protection (Ex Codes)

| Code | Method | Description |

|---|---|---|

| d | Flameproof | Contains explosion inside enclosure |

| e | Increased Safety | Avoids sparks and high temps |

| i | Intrinsic Safety | Limits energy to avoid ignition |

| p | Pressurization | Protective gas inside equipment |

| o | Oil Immersion | Immerses parts in oil |

| m | Encapsulation | Sealed in resin to block gases |

| n | Non-Sparking | For use in low-risk Zone 2 areas |

Gas Groups (Explosiveness Level)

| Group | Explosiveness | Examples |

|---|---|---|

| IIA | Low | Propane, methane |

| IIB | Medium | Ethylene, H₂S |

| IIC | High | Hydrogen, acetylene |

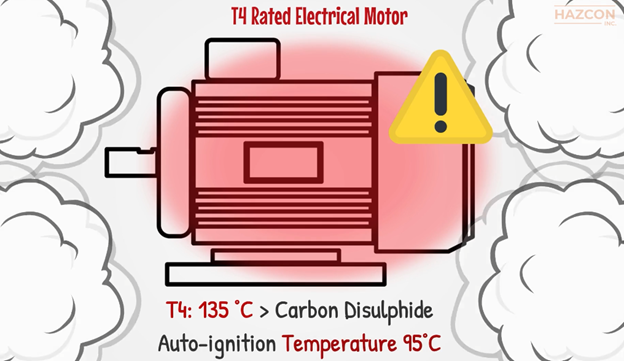

Temperature Classes

The equipment’s surface temperature must not exceed the ignition point of the surrounding gas/dust.

| Class | Max Temp |

|---|---|

| T1 | 450°C |

| T2 | 300°C |

| T3 | 200°C |

| T4 | 135°C |

| T5 | 100°C |

| T6 | 85°C |

What is EPL (Equipment Protection Level)?

EPL tells you how safe a device is in an explosive area:

- Ga / Da – Very high protection (Zone 0 / 20)

- Gb / Db – High protection (Zone 1 / 21)

- Gc / Dc – Normal protection (Zone 2 / 22)

It works alongside ATEX categories to define safe usage worldwide (especially under IECEx standards).

Final Thoughts

Understanding ATEX and explosion-proof markings is essential for selecting safe equipment in environments with explosive risks. From gas groups to temperature classes, every code plays a vital role in protecting people and assets.